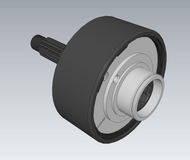

The Aerospace-Inspired Viscous Coupler R8/Gallardo Owners Actually Need

Posted by Stephen D Dunn on Sep 28th 2025

We have re-engineered the R8 (non-Haldex) / Gallardo viscous coupler into a component that meets the highest standards. Our product is made from billet 40CrMo steel, inspired by aerospace technology, and designed to be serviceable, modular, and rebuildable. It maintains its geometry under heat, allows for behavior tuning, and can withstand significant abuse.

Critical internal components are manufactured using Sinker EDM technology, which ensures that the splines, pockets, and lands are burr-free and dimensionally precise. This means that silicone shear remains consistent, and you can easily use either OEM-format plates or AKDBuilt packs, which are available in both 316L and 304 stainless steel options, without encountering tolerance issues.

Our coupler is a true platform with features such as snap-ring assembly for easy teardown, replaceable Buna-N O-rings (both round and square), published tolerances (±0.20 mm / ±0.20°), and a broad tuning range using commonly available silicone fluids (ranging from ~40K to 200K+ cSt). This allows viscosity, end-play, and fill volume to adjust the torque curve for various uses—be it street, track, roll, or drag racing.

We validated our prototype in real-world settings: Horse Power Lounge tested it on a ~2,800 hp TX2K Gallardo using 100K cSt fluid. The results were impressive—clean launches, repeatable hot passes, zero leak-down, and no reports of thermal fade.

In contrast, the OEM sealed unit has issues like fluid breakdown, seal leakage, air ingestion, and thin or crimped housings that distort under high temperatures. Moreover, there is no option for servicing it, and typical installation costs range from $3,400 to $7,500 for a unit that cannot be fine-tuned.

This product was developed under the guidance of Stephen D. Dunn Sr. (Chief Engineer and CEO of AKDBuilt Performance Inc.), who has 28 years of aerospace experience and a background in Information Technology and Engineering Technology. The project was delivered on schedule, overseen by Jeneen D. Dunn (Program Director at Project Planning & Controls LLC), who managed budgeting, procurement, supplier qualification, risk management, and change control.

This is not just a simple “repair.” It is a configurable driveline component built for reliability, thermal stability, and long-term value. If you actively use your car, consider stopping the purchase of consumables and start specifying durable components. Feel free to reach out to us to configure a solution tailored to your power requirements, tires, and driving venues.

AKDBuilt Performance Inc